|

XIAMEN MASCERA TECHNOLOGY CO.,LTD.

|

High Precision Alumina Al2O3 Ceramic Rods with Polishing

| Price: | 8.0 USD |

| Payment Terms: | T/T,WU,Paypal |

| Place of Origin: | Fujian, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

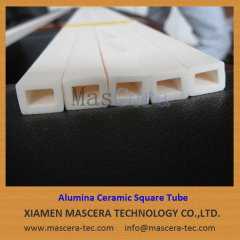

1. Alumina Ceramic Rods

2. Good wear resistance

Electrical insulation

High mechanical strength

Alumina Ceramic, also known as Aluminium Oxide or Al2O3, it is the one of the most widely used technical ceramic materials. Alumina ceramic components can be manufactured in a range of purities to suit for different applications. Forming methods will vary with the different size, shape and using requirement of products. Alumina ceramics are mainly used for mechanical, electrical, high temperature applications.

Alumina Ceramics can be made into different shapes e.g. rods, tubes, rings, plates, discs and other complex shapes according to customers' requirements with high precision.

Product Feature

Good strength and stiffness

Good hardness and wear resistance

Good corrosion resistance

High thermal conductivity

High temperature resistance

Electrical insulation

Low dielectric constant

Data Sheet for Materials

| Purity | 95% Alumina | 96% Alumina | 99% Alumina | 99.5% Alumina | 99.7% Alumina |

| Color | White/Pink | White | Ivory | Ivory | Ivory |

| Density (g/cm3) | 3.65 | 3.72 | 3.88 | 3.90 | 3.92 |

| Water Absorption (%) | 0 | 0 | 0 | 0 | 0 |

| Moh's Hardness | 9 | 9 | 9 | 9 | 9 |

| Flexural Strength (Mpa) (25℃) | 352 | 358 | 364 | 379 | 375 |

| Compressive Strength (Mpa) (25℃) | 2000 | 2068 | 2500 | 2600 | 2500 |

| Thermal Conductivity (W/m.k) (25℃) | 18-25 | ≥24 | 27 | 30 | 30 |

| Thermal Expansion Coefficient (25-1000℃)(10-6mm/℃) | 8 | 8 | 8 | 8 | 8 |

| Therma Shock Resistance △T(℃) | 220 | 220 | 180-200 | 180-200 | 180-200 |

| Max. Working Temperature (℃) | 1500 | 1650 | 1700 | 1750 | 1750 |

| Dielectric Strength (kv/mm) | 16 | 17.2 | 20 | 22 | 22 |

| Electrical Resistivity (Ω.cm) (25℃) | 1014 | 1014 | 1014 | 1014 | 1014 |

| Dielectric Constant (@1MHz, 25℃) | 9 | 9 | 9.7 | 9.7 | 9.8 |

| Dielectric Loss (tan delta) (@1MHz, 25℃) | 0.0004 | 0.0002 | 0.0001 | 0.0001 | 0.0001 |

Application

The typical application of Alumina Ceramics include:

Seal Rings

Plungers or pistons for valves

Electronic substrates

High temperature thermocouple tubes

Textile eyelets or guides

Electrical insulators

Wear resistant nozzles

Ceramic parts for high temperature furnace